How to Wind Perfect Coilgun Coils

Let's start with the goal: A coil with no core, and perfectly flat windings.

Let's start with the goal: A coil with no core, and perfectly flat windings.For large wire or small numbers of layers this isn't too hard. But for coils using small wire and a large number of layers it's basically impossible.

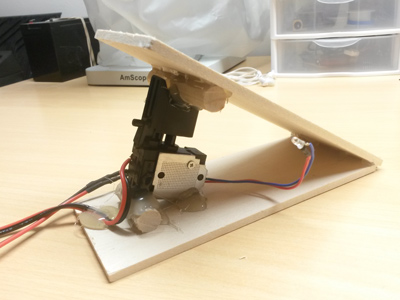

As you can see, with this method you can create coils with 15+ layers that are still perfectly flat.

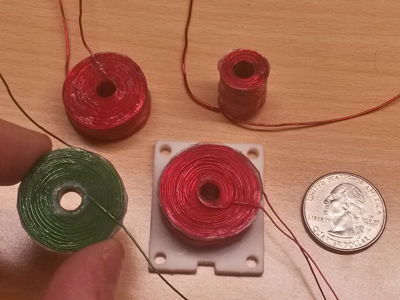

What makes these coils possible is a good jig. Here's my setup. I won't go into the construction because it's more or less self-explanatory, but I will go over the parts and why they're important.

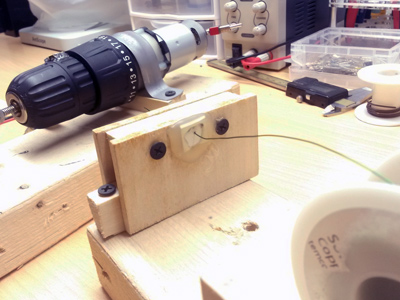

What makes these coils possible is a good jig. Here's my setup. I won't go into the construction because it's more or less self-explanatory, but I will go over the parts and why they're important.1. Motor

This came out of a cheap no-name powerdrill from Walmart. This lets you rotate the spool without taking your hands off the work. The fact that the motor, gearbox, and chuck came out as one unit makes it perfect for this application.

2. Spool

The coil is wound onto here. The spool can be dissembled afterwards to remove the coil.

3. Movable tensioner

The coil has to be kept under tension as you wind it. You can use a free hand for this, but having the tensioner allows you to take your hands off the jig without the coil becoming unwound.

4. Foot peddle

Made from the power-drill trigger.

5. Turn Counter

Necessary if you're trying to make coils with any kind of precision. This is a cheap counter unit from Amazon. It came with mounting hardware and the magnet.

This came out of a cheap no-name powerdrill from Walmart. This lets you rotate the spool without taking your hands off the work. The fact that the motor, gearbox, and chuck came out as one unit makes it perfect for this application.

2. Spool

The coil is wound onto here. The spool can be dissembled afterwards to remove the coil.

3. Movable tensioner

The coil has to be kept under tension as you wind it. You can use a free hand for this, but having the tensioner allows you to take your hands off the jig without the coil becoming unwound.

4. Foot peddle

Made from the power-drill trigger.

5. Turn Counter

Necessary if you're trying to make coils with any kind of precision. This is a cheap counter unit from Amazon. It came with mounting hardware and the magnet.

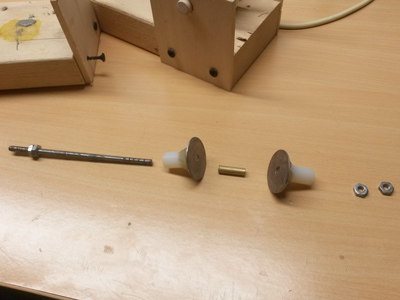

This is the spool. It's your standard coil winding form, but I glued some plastic spacers to the washers to keep them normal to the shaft. The tube is a piece of brass hobby-tubing.

This is the spool. It's your standard coil winding form, but I glued some plastic spacers to the washers to keep them normal to the shaft. The tube is a piece of brass hobby-tubing. I made one other modification to the standard form. Because our coil is going to be perfectly flat, we can't sneak the wire out from the inside layer. Therefore I've made a small hole through the washer and spacer for the wire to escape.

I made one other modification to the standard form. Because our coil is going to be perfectly flat, we can't sneak the wire out from the inside layer. Therefore I've made a small hole through the washer and spacer for the wire to escape.This washer has been used a lot...

Here's a close-up of the tensioner. It's just a drilled hole with a piece of rubber glued to one side.

Here's a close-up of the tensioner. It's just a drilled hole with a piece of rubber glued to one side.The wood parts form a simple slider. It's not absolutely necessary, but it's handy.